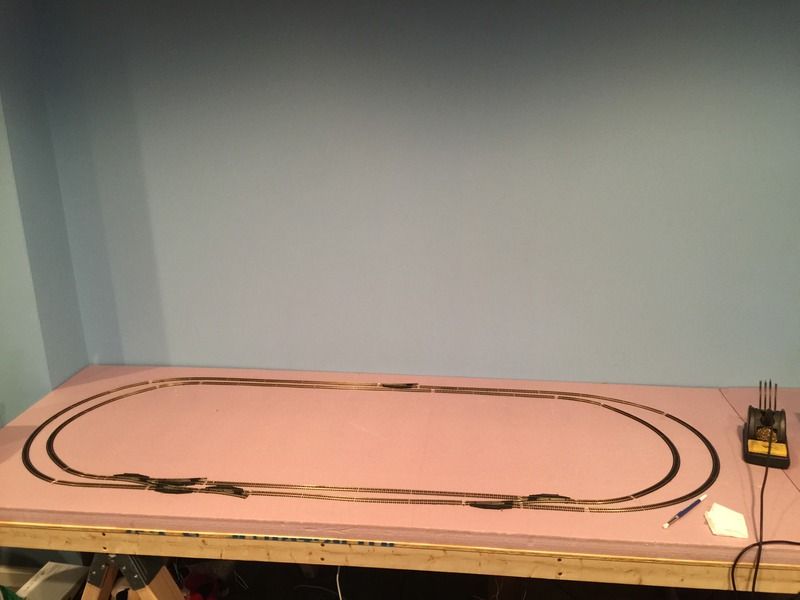

So I recently got my first section of track up and running, just for testing purposes I only soldered on one feeder wire for power to the track and it ran ok. It stumbled a little here and there but I figured the track needed cleaned better.

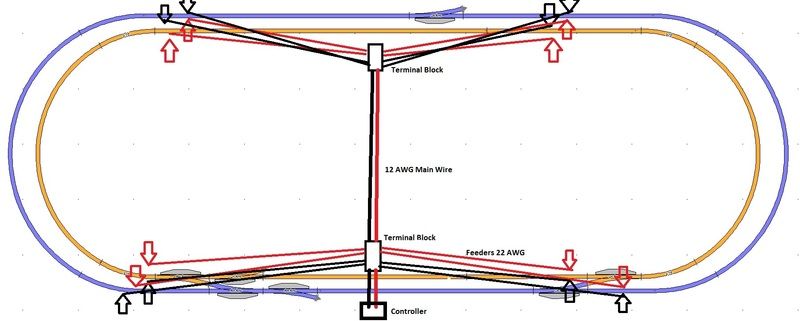

Last night I dropped more feeder wires connected to terminal blocks, and ran all my wires down through and under the table.

I tried running the train again and thought it was going to run so much nicer with more feeders but I was mistaken. The train won't even move a few inches without stalling out. I can touch it and it will re-connect and then just stall out again.

Any ideas on why this is happening?

What is the best thing to clean the track and the loco wheels with. Currently the only thing I have used is alcohol and a bristle brush?

Thanks

Last night I dropped more feeder wires connected to terminal blocks, and ran all my wires down through and under the table.

I tried running the train again and thought it was going to run so much nicer with more feeders but I was mistaken. The train won't even move a few inches without stalling out. I can touch it and it will re-connect and then just stall out again.

Any ideas on why this is happening?

What is the best thing to clean the track and the loco wheels with. Currently the only thing I have used is alcohol and a bristle brush?

Thanks