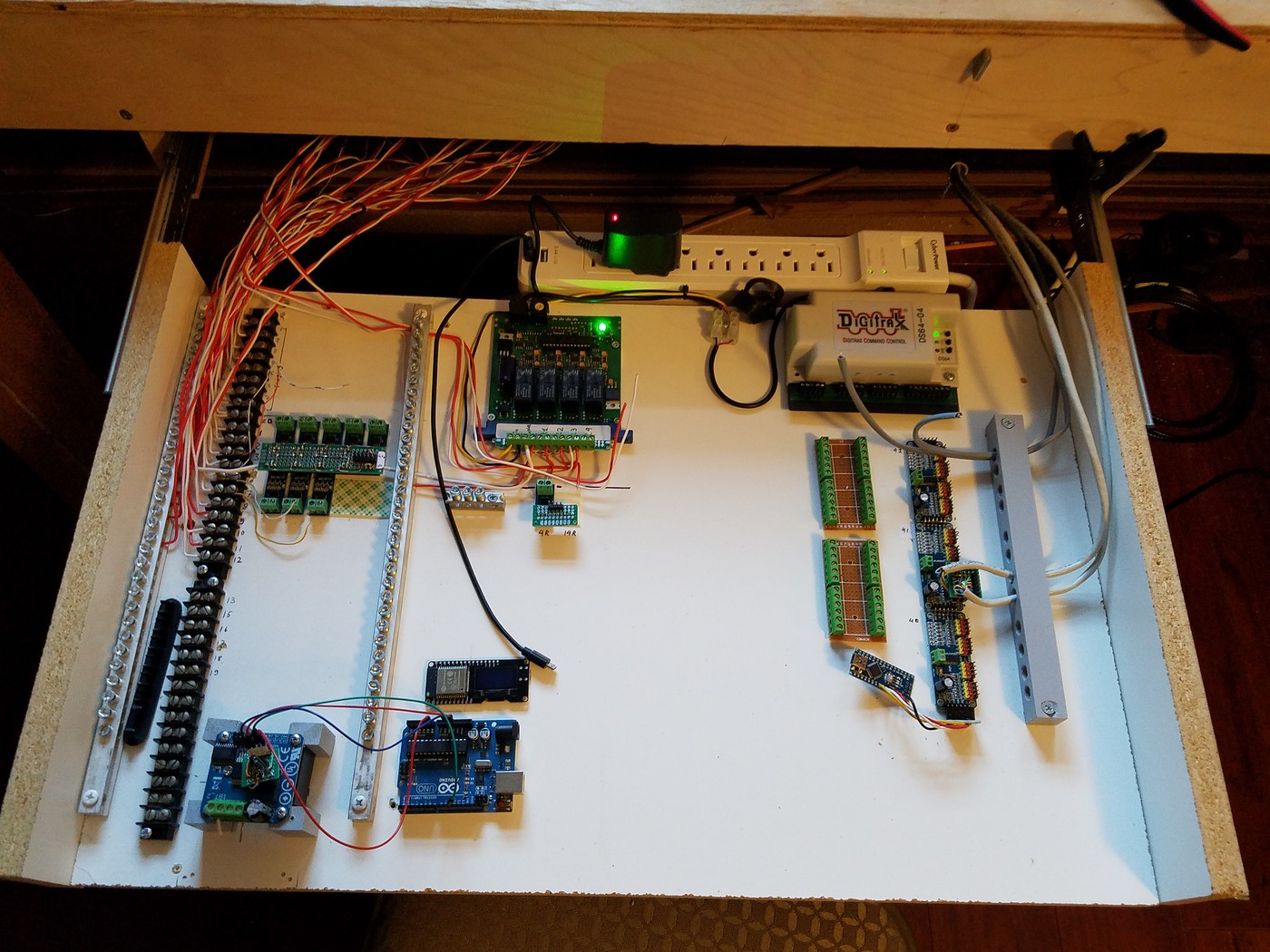

with most of the trackwork complete i'm focusing on wiring and electronics. desided to keep the digitrax decoder to drive the 4 peco coil switch motors I have in engine yard. decoder will only be used as capacitor discharge unit. rest of the turnouts use servo motors and are driven with 3 PCA9685 controllers connected to dedicated Arduino Nano as interface. Same Arduino will command the DS64 via opto-isolated circuit. created a quick sketch testing connectivity to JMRI via C/MRI - its a GO.

not so good on the detection side. as documented by other modelers ACS712 sensors are just not sensitive enough , current that typical HO engine pulls is barely above noise level of those devices (I did attempt noise filtering). not sure how I missed that fact while researching

already took the wires out but decided to take a picture before removing the devices.

plan B is Current Transformers. Ordered, but it looks like there are significant delays getting stuff from corona-virus'ed China.

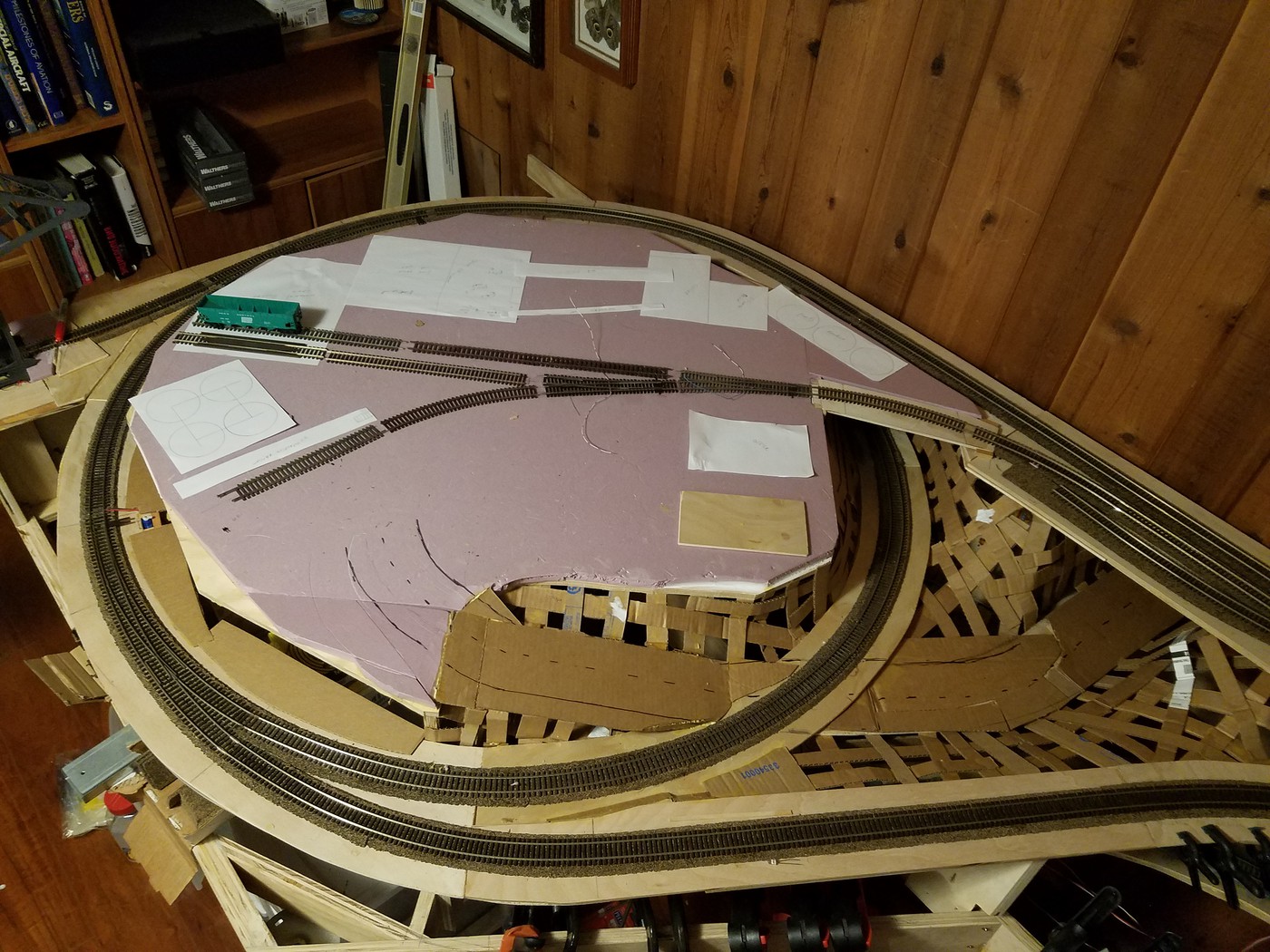

installed and stained most fascia boards and toned down that hot pink insulation some - now things look a bit more civilized.

Installed Dell all-in-one PC on a pivot mount. will serve as decided JMRI PC, digital touchscreen control panel and makes for a very convenient workstation for everything programming. youtube music - bonus

![Image]()